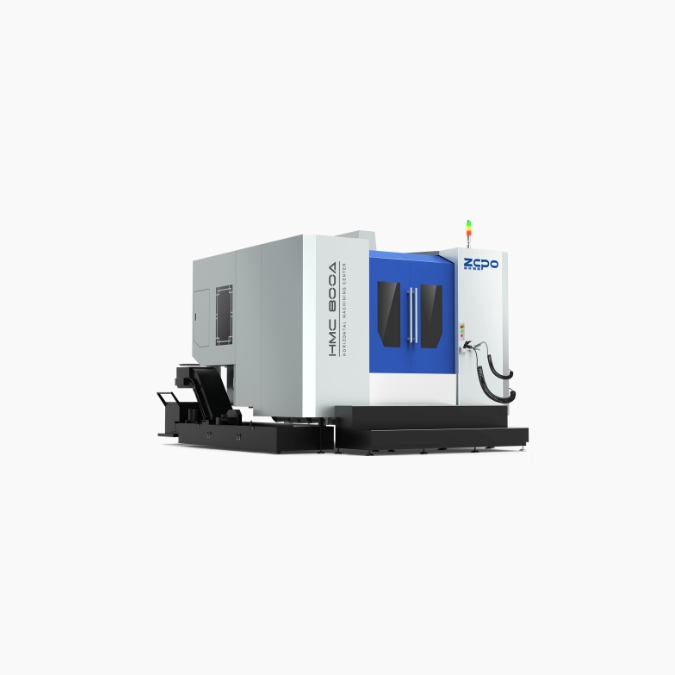

HMC800A Inverted T-Type Horizontal Machining Center

Single Worktable Design | High Precision 4-Axis Machining | Enhanced Rigidity

Technical Specifications

Worktable Size

800 × 800 mm

X/Y/Z Travel

1300/1000/1000mm

Spindle Speed

5300rpm

Rapid Traverse Rate

24/24/24m/min

Spindle Motor

15/18.5KW

Machine weight

15000kg

Positioning Accuracy

0.012mm

Repeatability

0.008mm

Spindle Taper

BT50

Machine Dimensions

5300*3970*3300mm

Tool Capacity

24 tools

Table Load Capacity

1200kg

Enhanced Inverted T-Type Structure

- Reinforced inverted T-type bed structure for maximum stability

- High precision grade P4 spindle bearings with extended lifespan

- Hardened and ground slideways with Turcite-B coating

- Advanced thermal symmetry design minimizes deformation

- Rigid machine structure for heavy-duty cutting operations

High-Power Spindle System

- High-torque, high-power spindle for heavy cutting

- Built-in encoder for rigid tapping and precise spindle orientation

- Advanced cooling system with temperature control

- Automatic tool changer with 60-tool capacity

- Optional 10,000 rpm high-speed spindle available

Advanced Control System

- FANUC 31i-B or Siemens 840D sl CNC system

- 17" high-resolution color LCD display

- High-resolution absolute position encoders

- Thermal compensation and error mapping

- Ethernet connectivity for remote monitoring and programming

- Advanced 3D simulation and collision avoidance

Applications

Automotive Components

Manufacturing of engine blocks, transmission cases, and large automotive components

Heavy Machinery

Precision machining of large machine frames, housings, and bases

Energy Sector

Production of turbine components, hydraulic parts, and energy equipment

General Manufacturing

Versatile machining of various medium-to-large precision parts