SPARK BED EDM Machine

Bed Type EDM | Precision Machining | Versatile Applications

Key Specifications

Max. Electrode Weight

100-200 Kgs

Max. Workpiece Weight

800-2000 Kgs

Work Table Travel (X)

300-700 mm

Work Table Travel (Y)

200-550 mm

Ram Servo Travel (Z-axis)

180-250 mm

Work Head Travel (W-axis)

180-400 mm

Max. Electrode to Table

420-850 mm

Oil Tank Capacity

250-980 Liters

Small Series

Medium Series

Large Series

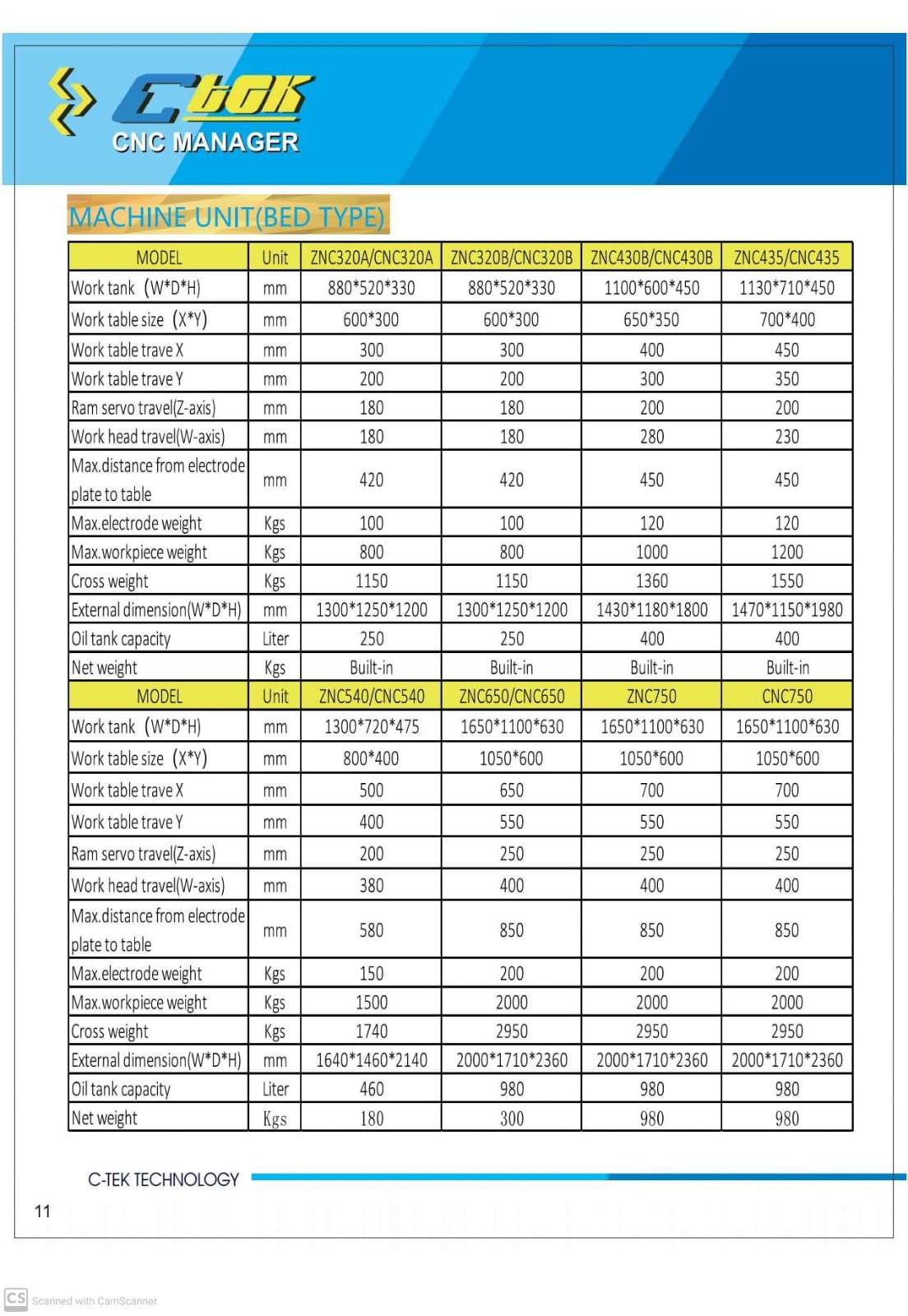

Small Series Models (ZNC/CNC 320A, 320B, 430B, 435)

| MODEL | Unit | ZNC320A/CNC320A | ZNC320B/CNC320B | ZNC430B/CNC430B | ZNC435/CNC435 |

|---|---|---|---|---|---|

| Work tank (W×D×H) | mm | 880×520×330 | 880×520×330 | 1100×600×450 | 1130×710×450 |

| Work table size (X×Y) | mm | 600×300 | 600×300 | 650×350 | 700×400 |

| Work table travel X | mm | 300 | 300 | 400 | 450 |

| Work table travel Y | mm | 200 | 200 | 300 | 350 |

| Ram servo travel (Z-axis) | mm | 180 | 180 | 200 | 200 |

| Work head travel (W-axis) | mm | 180 | 180 | 280 | 230 |

| Max. electrode to table | mm | 420 | 420 | 450 | 450 |

| Max. electrode weight | Kgs | 100 | 100 | 120 | 120 |

| Max. workpiece weight | Kgs | 800 | 800 | 1000 | 1200 |

| Gross weight | Kgs | 1150 | 1150 | 1360 | 1550 |

| External dimension (W×D×H) | mm | 1300×1250×1200 | 1300×1250×1200 | 1430×1180×1800 | 1470×1150×1980 |

| Oil tank capacity | Liter | 250 | 250 | 400 | 400 |

Precision Engineering

- Bed-type structure for enhanced stability and rigidity

- Precision ground ballscrews for accurate positioning

- Advanced servo control systems for smooth operation

- Thermal compensation technology for consistent accuracy

- Rigid construction minimizes vibration during operation

Advanced Control Systems

- ZNC and CNC control options available

- User-friendly interface with graphical display

- Multiple machining modes and parameters

- Automatic electrode wear compensation

- Program storage and recall capabilities

- Real-time monitoring of machining conditions

Standard Features

- Built-in oil filtration and circulation system

- Automatic oil level control

- Advanced dielectric fluid system

- Emergency stop and safety interlocks

- Work tank with splash protection

- Centralized lubrication system

Applications

Mold & Die Making

Precision machining of injection molds, stamping dies, and forging dies

Aerospace Components

Manufacturing of turbine blades, engine components, and structural parts

Automotive Industry

Production of transmission parts, fuel injection components, and tooling

General Machining

Versatile machining of complex parts from various conductive materials